Laminate Technologies: Innovations, Applications, and Future Trends

Laminate technologies have revolutionized multiple industries, ranging from construction to electronics. These technologies offer versatile, durable, and cost-effective solutions, forming the backbone of modern manufacturing and design. This article explores the history, types, applications, and future directions of laminate technologies.

What Are Laminate Technologies?

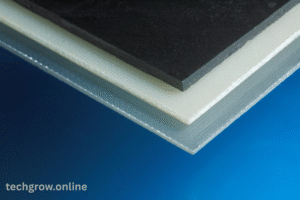

Laminate technologies refer to the materials and methods used to create layered composite structures by bonding multiple layers of materials such as paper, wood, plastic, or metal. These layers are fused using adhesives, heat, or pressure to create a composite material with enhanced properties.

The goal of laminating is to merge the best characteristics of each layer—such as strength, flexibility, or appearance—into one unified product. This process includes various techniques such as high-pressure lamination (HPL), low-pressure lamination (LPL), and vacuum lamination, each serving distinct industrial needs. These methods are essential in producing items like laminate flooring, circuit boards, and even aerospace components.

Key Advantages of Laminate Technologies

Laminate technologies are favored across sectors due to several significant benefits:

-

Durability: Resistant to wear, moisture, and impact—ideal for high-traffic areas.

-

Versatility: Customizable for specific applications, from decorative to structural.

-

Cost-Effectiveness: Offers premium finishes at lower costs than solid materials.

-

Sustainability: Increasing use of eco-friendly materials and processes.

-

Aesthetic Flexibility: Replicates natural material appearances without limitations.

These features make laminate technologies a preferred choice for businesses seeking reliable, multifunctional materials.

Types of Laminate Technologies

Understanding the different types of laminate technologies helps identify the best fit for various applications.

1. High-Pressure Laminates (HPL)

High-pressure laminates are produced by compressing layers of kraft paper, resin, and decorative surfaces under high temperature and pressure. These laminates are:

-

Highly durable against heat, scratches, and chemicals.

-

Used in furniture (countertops, cabinets), interior design (wall panels), and commercial spaces (hygienic surfaces in hospitals and retail).

HPLs are considered an industry standard for strength and flexibility.

2. Low-Pressure Laminates (LPL)

Low-pressure laminates, also called melamine laminates, involve bonding a decorative surface onto MDF or particleboard at lower pressure. They are:

-

Cost-effective for general-purpose use.

-

Found in residential furniture (wardrobes, shelves), laminate flooring, and office furniture (desks, partitions).

While not as strong as HPLs, LPLs offer economical options for less demanding environments.

3. Vacuum Lamination

This advanced method uses vacuum pressure to eliminate air pockets and ensure a perfect bond. Applications include:

-

Automotive interiors (dashboards, panels).

-

Aerospace components that need to be lightweight yet strong.

-

Electronics, especially flexible printed circuits and screens.

4. Thermoplastic Lamination

Involves fusing plastic layers using heat to form recyclable and moldable materials. It’s gaining popularity in eco-conscious industries focused on sustainability and lightweight components.

Applications of Laminate Technologies

Laminate technologies are pivotal across many sectors:

1. Building and Architecture

Used in flooring, wall cladding, and roofing, laminates offer:

-

Weather resistance

-

Ease of installation

-

Aesthetic versatility

High-pressure laminates are widely used in both interior and exterior architectural applications.

2. Furniture Manufacturing

Laminates are a go-to material for the furniture industry, offering:

-

Affordable design options

-

Durability and easy maintenance

-

Decorative finishes like wood grain, stone, and abstract styles

From kitchen cabinets to office desks,this technologies enhance product appeal and performance.

3. Electronics and Technology

In electronics, laminate technologies are critical for:

-

Printed circuit boards (PCBs) via copper-clad laminates (CCLs)

-

Wearable tech and foldable devices through flexible laminates

They provide both mechanical support and electrical insulation.

4. Automotive and Aerospace

Used in producing:

-

Carbon fiber laminates for structural integrity in aircraft

-

Interior panels and dashboards in automobiles

-

Lightweight components to improve fuel efficiency and performance

5. Packaging and Consumer Goods

Flexible laminates are extensively used in packaging:

-

Food and beverage items

-

Medical supplies

-

Household products

These laminates improve durability, shelf life, and environmental protection.

Advancements in Laminate Technologies

Continuous innovation is shaping the future of laminate materials and methods. Key developments include:

-

Eco-Friendly Laminates: Bio-based resins and recycled materials support sustainability and green building goals.

-

Smart Laminates: Embedded with sensors for touch interaction and data transmission in IoT devices.

-

Anti-Microbial Laminates: Reduce bacterial growth—ideal for healthcare and public spaces.

-

3D Laminates: Allow seamless wrapping of curved surfaces, expanding design potential in automotive and furniture sectors.

SEO Best Practices for Laminate Technologies Content

To effectively market laminate technology products, implement these SEO strategies:

-

Keyword Optimization: Use primary terms like “laminate technologies,” “high-pressure laminates,” and “laminate flooring.” Support with secondary keywords like “sustainable laminates” and “laminate manufacturing.”

-

User Intent Matching: Answer key queries such as “what are laminate technologies” and “benefits of laminates.”

-

Internal Linking: Link related product pages (HPL, LPL) and case studies.

-

Mobile Optimization: Ensure responsive design for mobile users.

-

Visual Content: Use images, infographics, and videos to improve engagement and dwell time.

The Future of Laminate Technologies

Exciting trends are on the horizon for laminate technologies:

-

Nanotechnology: Nano-laminates with improved strength, conductivity, and heat resistance.

-

Recyclable Laminates: Essential in supporting circular economies and eco-conscious manufacturing.

-

Automation and AI: Streamlined processes for efficient, cost-effective production.

-

Customization: Digital printing enables personalized designs for homes, offices, and retail.

These advancements ensure this technologies remain central in addressing evolving consumer demands and industrial innovation.

Conclusion

This technologies continue to transform the way we build, furnish, and innovate. From long-lasting flooring to high-performance electronics, laminates offer unmatched durability, flexibility, and cost savings. With new trends focusing on sustainability, customization, and intelligent functionality, laminates will play an increasingly significant role in both industrial and consumer sectors.

Whether you’re sourcing laminate flooring for home improvement or high-pressure laminates for commercial use, understanding these technologies equips you to make smarter decisions and capitalize on this ever-evolving industry.